How to install the D-Track-LT

What is D-Track-LT®?

Developed in Europe for the truck and bus industry, D-Track-LT® is a complete cable management system made of flexible PVC. This unique wraparound cable routing system offers several advantages over split, coiled hoses.

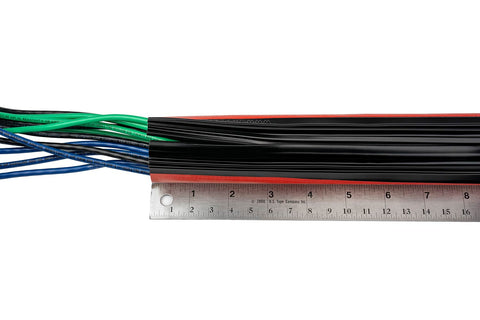

Because it is made from a flexible PVC compound, there are no sharp edges to damage wires during cable assembly. The patented external locking system allows for much higher cable fill rates and easier accessibility for faster installations.

Wraparound or side entry allows for a modular cable design, reducing Total Installation Cost (TIC). The D-Track-LT® closure method ensures that the cables are not exposed to external contamination, reducing Total Cost of Ownership (TOC). This product is currently used in trucks and buses manufactured by Daimler/Chrysler, DAF, Freightliner, Kenworth and PACCAR.

D-Track-LT® is ideal for use in automotive applications where cable bundles must be protected from the harsh environment of constant road use. The patented expansion feature allows for cable growth as designs change. The track locking system is also available for many jacket materials, including extruded films and coated fabrics.

Track closure vs. curve position

Installation instructions:

- Always size the zipper tubing jacket at least 1/8" larger than the maximum cable diameter. If severe cable bending is expected, it is recommended to increase the jacket diameter beyond the 1/8" requirement.

- Always install Zipper-technik sleeves with the rail facing the outside of the bend radius. Failure to position the sleeve in this manner may result in the chain “jumping” due to chain distortion.

- If the design does not require regular opening of the casing, it may be desirable to seal the rail with ZT-TAPE.

- The most common causes of tracks bursting are:

- Improperly closed track

- Wrong sized jacket, less than 1/8 inch oversize

- The track is different than outside the curve radius

SLD Slider – For use with short runs

The SLD tool is a low-cost, plastic slider tool for locking Zipper-technik D-Track-LT® products. It is primarily intended for use in low-volume production line applications or field installations. The tool engages the outside tabs of the D-Track-LT® profile and engages the lock as it is slid along the cable guide.

This tool allows for quick and easy closing of D-Track-LT while minimizing operator fatigue. The tool is used after the two rail halves have been manually pressed together with fingers at the jacket end. The tool is then slid along this short section of pre-closed rail. As the tool is slid along the cable guide, it pre-forms the jacket around the cable, forming a closed, continuous tube.

ZTD-SP PLIERS – For us with long runs

The ZTD-SP tool is a stainless steel pincer tool designed to close Zipper-technik D-Track-LT® products. It features two roller wheels that grip under the outside eyelets of the D-Track-LT profile. Squeezing the handles together contracts the locking mechanism. As the operator pulls the tool along the cable, the D-Track-LT jacket forms around the harness and snaps together to form a continuous tube. This tool allows for quick and easy closing of D-Track-LT® while minimizing operator fatigue. The ZTD-SP tool is primarily intended for use in high volume production lines where hundreds or thousands of feet of material must be closed.

General installation instructions:

Both the "SLD" and "ZTD-SP" tools will pull the two edges of the D-Track-LT® jacket together for you. However, you will find that removing all of the "spool sets" will cause kinks or twists and bringing the two edges together - the edges being close together will make the installation process easier. Having an assistant to prepare the D-Track-LT® tubing around the cable about 18-24 inches (0.5 meters) ahead of you will increase the speed of installation. If you are working alone, you can wrap a cable tie loosely around the Zippertubing jacket and cable assembly to preform the jacket and bring the edges of the jacket close together. Slide the cable tie along as you close the jacket.

The ideal installation temperature for D-Track-LT® is above 60°F (15.5°C). D-Track-LT® consists of a very thick section of track that blends into a thin film material. Because of this mass difference, the thicker material tends to take on the shape of the spool it was packaged on. This memory phenomenon is exacerbated by low temperatures and can cause the material to curl up and twist as it is unrolled from the spool. If installations must be done at temperatures below 60°F (15.5°C), you may find that preheating the coils in an oven at 100°F (38°C) for about two hours will help minimize coil set and make the material much more pliable. When working with shorter lengths at low temperatures, you can heat the material with a hair dryer to minimize coil set memory.

When using the plastic slide "SLD", a lot of friction occurs with long assembly lengths. Periodically lubricating the tool and the rail surface with a few drops of isopropyl alcohol (IPA) will reduce tool friction and facilitate the closing process. Isopropyl alcohol (IPA) is a flammable liquid, so obtain approval from your Process Engineering Department before performing any tool lubrication procedure.

Closing D-Track-LT® with the SLD Slider Tool

Step 1: Wrap the end of the D-Track LT® material around the cable to be covered. Using the thumb and forefinger of both hands, push the arrow approximately 25 mm (1.0 in.) down the end of the tube into the cavity of the appropriate channel.

Step 2: Slide the “SLD” tool over the two outer ribs of the pre-locked section.

Use the SLD tool to work approximately 25 mm (1.0 inch) along the rail.

Step 3: Grasp the closed end of the latch with your thumb and forefinger, then begin sliding the tool along the length of the cable by pulling the tool along with the thumb and forefinger of your other hand. Once 10-20 cm (6-8 inches) of the rail is closed, you can grasp the entire cable/sheath assembly with your hand while pulling the tool along.

Closing D-Track-LT® with the ZTD-SP pliers tool

Step 1: Wrap the end of the D-Track-LT material around the cable to be covered. Use your thumb and the index finger of both hands to push the arrow into the mating channel cavity for a distance of about 1.0 inch (25mm) at the tubing end.

Step 2: Open the handles of the "ZTD-SP" tool and align the two roller wheels over the two outer locking ribs. Squeeze the tool handles together to lock the roller wheels into the grooves.

Step 3: Grasp the closed end of the D-Track LT® Latch with your thumb and forefinger, then begin pulling the "ZTD-SP" tool along the length of the cable. Once 10-20cm (6-8") of the track is closed, you can grasp the entire cable assembly with your hand while pulling the tool along.

Sealing of extruded Zippertube rails

All Zippertubing products that use extruded closure rails (except Type FEP) can be permanently sealed after closure using the following method. Under normal circumstances, a properly closed Zippertubing rail does not require sealing after closure. However, in some applications where an environmentally or tamper-evident seal is desired, or extreme abuse is expected, the post-sealing process can ensure that the rail does not inadvertently reopen.

ZT-TAPE

This method involves applying a 1" wide strip of Zippertubing's ZT Tape to the center of the interlocking rail parting line after the rail is closed. The ZT Tape is a UL-510 recognized, fire-retardant polyurethane film tape with an acrylic adhesive backing. The adhesive is compatible with both PVC and PFR rail materials and is easy to apply. The tape sealing method provides additional closure strength, improves environmental sealing, and is an environmentally friendly process.

CAUTION: ZT tape is highly elastic and must be applied to the track in a relaxed state. Stretching the tape during installation may cause the film to separate from the adhesive if the assembly is stored or shipped in a rolled up or severely bent state.

Re-entry procedure

Background: Zippertubing's D-Track-LT® product is designed as a heavy-duty harness jacket system that allows for easy installation through the use of a side entry design combined with a highly flexible material and an extremely strong closure mechanism. The closure mechanism is designed to provide high closure strength (35 lbs/in typical), creating a jacket that stays closed during operation and keeps a system free from external contaminants.

Reentry Expected: In rare cases, the user may need to re-open a closed D-Track LT® hose jacket. If the user anticipates numerous reentry cycles (as may occur during prototyping), the jacket should not be fully closed until all work is completed. One or both ends should be left open on the last 2.0 inches of the hose to allow for easy reentry. If the ends remain open, the user can simply pull the track halves apart to reopen the hose.

Opening a fully closed jacket

Step 1: If re-entry is required after the entire D-Track-LT® jacket has been fully closed, the re-opening process should begin at the end of the tubing. Follow the steps shown below to disconnect the track locking mechanism, then pull the track apart to gain access if necessary.

Step 2: Hold the hose assembly so it cannot move. Continue to apply pressure to the screwdriver to prevent it from slipping out of the locking mechanism. Rotate the screwdriver to the vertical position. This will push the arrowhead barb out of the locking channel side. When the barb disengages from the channel, release the inward pressure on the screwdriver to avoid forcing the blade into the cables or hoses in the hose jacket.

Step 3: Once the two halves of the rail are separated, remove the screwdriver, grasp the two halves of the rail with your thumb and forefinger, and pull the two halves apart about 1 inch.

Step 4: Once the splint is separated, reposition your thumb and index finger to grasp a larger portion of the tubing on each side of the splint. Continue separating the tubing into a flat sheet as needed.